Reciprocating Friction Tester sourcing|hfrr tester : manufacturer Application It is mainly used to test and evaluate the tribological properties of materials or surface coatings. The tester is used to simulate the rotation and linear reciprocating motion under a certain test force. Resultado da 11 de out. de 2023 · Aroomi Kim’s South Korean background adds an enticing element to her content, showcasing her unique ethnicity and .

{plog:ftitle_list}

25 Telegram Mews is a master-planned and strategically located project, nestled at Toronto in Ontario, offering good connectivity to major facilities and social infrastructure alike. .

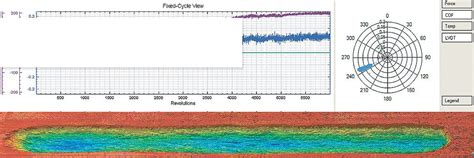

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module .

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the .

linear wear friction testing

linear friction tribometer test

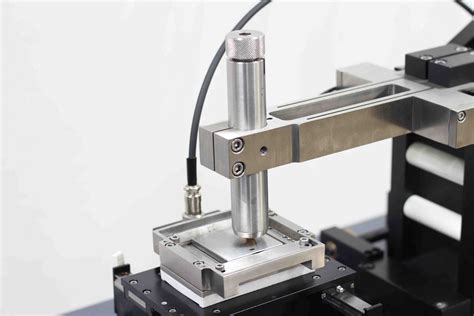

To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism.The machine uses weight loading 50g-2000g; automatic constant loading; dynamic alternating loading: (sine wave loading, triangle wave, gradient loading) three loading modes, which can simulate point, line, and surface contact forms .Application It is mainly used to test and evaluate the tribological properties of materials or surface coatings. The tester is used to simulate the rotation and linear reciprocating motion under a certain test force.Company Introduction: Jinan yihua tribology testing technology Co., Ltd. is the first professional tribology testing technology research and test equipment development company, is a scientific research, production, sales, technical services, academic exchanges in one of the high-tech enterprises, is the national tribology society member unit. Our company has first-class .

The High-speed reciprocating friction and wear tester is mainly used for testing the friction and wear performance of materials and surface coatings. The machine uses weight loading 50g-2000g; automatic constant loading; dynamic alternating loading: (sine wave loading, triangle wave, gradient loading) three loading modes, which can simulate .1. Maximum test force: 500N 2. Speed range: 1-2000 rpm 3. Frequency range: 1-80Hz 4. Maximum reciprocating friction: 100N 5. Maximum rotating torque: 4.7Nm 6. Reciprocating displacement range: ± 6mm 7. Reciprocating friction forms: ball-disk, pin-disk and pillar tile 8. Rotary friction type: ball-disk, pin-disk and end face 9.Sourcing Solutions Source from Industry Hubs Customize Your Products MEI Awards-Winning Products Smart Expo; Service New User Guide Product Alert . (high frequency reciprocating friction and wear testing machine), and other special machine. It can manufacture various kinds of friction pairs, such as point, line, surface and compound motion .LPR’s tribotesters measure material mechanical properties, friction, and wear characteristics using various types of rotating and reciprocating sliding contact test methods. By providing a wide range of control and recording parameters, our tribometers generate more accurate simulations of material wear and friction to determine the .

MFT-R4000 high speed reciprocating friction wear tester. MFT-R4000 is a multifunction tester used for evaluating the high speed reciprocating friction and wear performance of materials and films under different environment with variation of load, frequency, temperature and gas. It is also applied in the friction and wear measurement under .The testing machine in accordance with China's industry standard SH/T0765-2005 "diesel lubrication evaluation method (High frequency reciprocating testing machine method)" (ISO12156-1: 1997, MOD standard method) requirements of the technical indicators designed, the technical indicators meet the requirements of SH/T0765, ISO 12156.1-2016, ASTM D6079 . The rig used is a slightly modified version of the one developed for unidirectional sliding by the present authors in Bin Jaber et al. [36].The approach is somewhat similar to the sled-type friction test in ASTM D1894 [37].A schematic representation of the rig is shown in Fig. 2 (with numbers indicating the key components). The contact adopted for the study was a flat .

Friction stroke: 104 ±3mm: Movement mode: hand reciprocating: Friction head: fleece fabric: 19mmx25.4mm : Friction head: Other fabrics: diameter 16mm: Cotton rubbing: cloth Fleece fabric:25 ±2mm×100±2mm : Cotton rubbing: cloth Other fabrics:50 ±2mm×50±2mm: Test speed: 60 ±2r/min: Reciprocating stroke: 104 ±3mm: Friction head diameter .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of . Aiming at the reciprocating motion existing in the space rolling bearing, the wear characteristics of the reciprocating friction of MoS2 were studied. The friction simulation between Fe–Ni–Cr substrate and MoS2 is simulated by mixing multiple potential functions. and came to the following conclusions: . such as gas and magnetic suspension .

Historical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal . Management System Certification: ISO 14000, ISO 20000, HSE, ISO 14064, QC 080000, SA 8000, BS 25999-2 The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius . The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency.

high frequency reciprocating rig

Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004 In brief, an in-house-built tribometer was used and operated in ball-on-flat linear reciprocating test conditions with a stroke of ~1 mm at a reversing frequency of ~1 Hz. Plane polished titanium alloy (Ti6Al4V) samples were used along with 10 mm diameter counterbodies (hardened 100Cr6 steel or Si 3 N 4 ceramic) in dry or oil-lubricated .Download scientific diagram | Linear reciprocating sliding friction and wear tester. from publication: The Relationship between the Model of the Laser Biomimetic Strengthening of Gray Cast Iron .Company Introduction: Jinan yihua tribology testing technology Co., Ltd. is the first professional tribology testing technology research and test equipment development company, is a scientific research, production, sales, technical services, academic exchanges in one of the high-tech enterprises, is the national tribology society member unit. Our company has first-class .

Rtec SRV Tester studies friction and wear of lubricants and grease. ASTM, DIN, ISO compliant, with wide test range. Stroke control from 5um . Dedicated SRV tester for reciprocating friction and wear analysis. SRV Test on Multi Function Tribometer MFT-5000. SRV test on the MFT-5000 allows several other friction, tribology, wear tests on the . The more usual arrangement is Fig 1 The simple reciprocating friction and wear tester 0301-679X/80/010011"05 .00 1980 IPC Business Press TRIBOLOGY international February 1980 11 Moore and Noah - Friction and wear tester pneumatic loading of the test sample, as shown in Fig 3. Here, a pneumatic load cylinder under the action of air pressure .

Company Introduction: Jinan yihua tribology testing technology Co., Ltd. is the first professional tribology testing technology research and test equipment development company, is a scientific research, production, sales, technical services, academic exchanges in one of the high-tech enterprises, is the national tribology society member unit. Our company has first-class .

Polymer Testing 9 (1990) 195-211 Reciprocating Sliding Friction and Wear Test Apparatus S. M. H. Benabdallah Department of Mechanical Engineering, Ecole Polytechnique de Montrral, PO Box 6079, Station 'A', Montreal, Quebec, Canada, H3C 3A7 (Received 4 November 1989; accepted 2 December 1989) ABSTRACT As the friction and wear properties of polymers are .To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure .

high frequency reciprocating equipment

high frequency friction tester

hfrr tester for sale

hfrr tester

Resultado da 28 de fev. de 2022 · Aquarius Sabara Bar, Sao Paulo: See 14 unbiased reviews of Aquarius Sabara Bar, rated 5 of 5 on Tripadvisor and ranked .

Reciprocating Friction Tester sourcing|hfrr tester